Smooth and Quiet, Precision Manufacturing, Innovative Research and Development, become the pet phrases between staffs of Youlisi in factory.

Concentrate on products has always been the kingpin that Youlisi adhering to for more than 20 years. From the smoothness and quietness of each caster wheel, to the innovative research and development of push latch, from each plastic part to the processing of molds, we always adhere to precision manufacturing, to produce excellent products for allover the world.

When we visited our global strategic partners, our clients jointly put forward a demand. In the process of the rise of customization furniture industry, consumers' demand for drawers has changed again, from small and narrow drawers to large and wide drawers, from with handles to without. The higher requirements on load-bearing and applicability of the drawer slides. In this way, high-quality, super-smooth running, and strong load-bearing drawer slides are born.

We integrate 20 years of technical precipitation, integrate the characteristics of smooth damper, mute and high load-bearing caster into the design of drawer slides, select premium raw materials, after 5 years of continuous innovation and never-stop testing, the official launch meets our standard - Youlisi YC series & YL series concealed drawer slide.

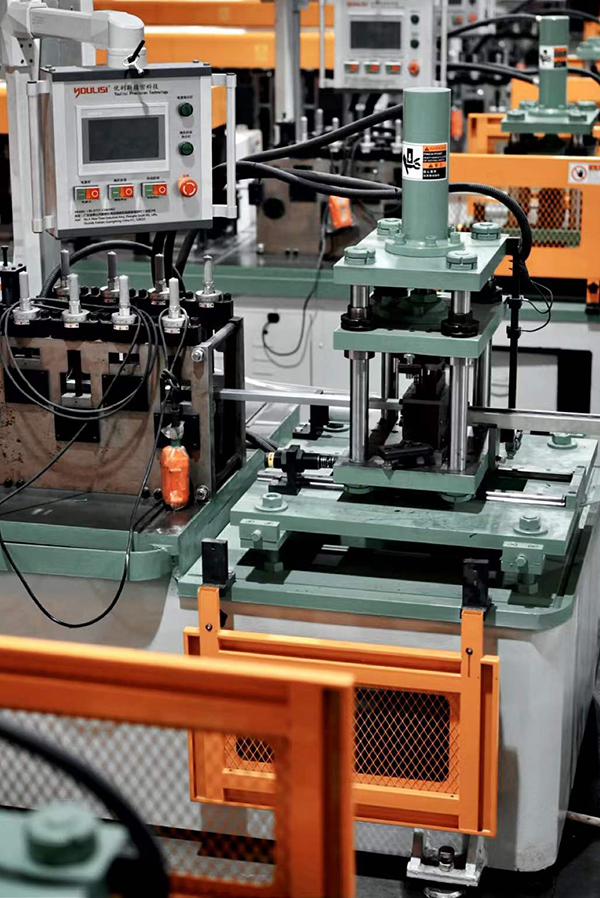

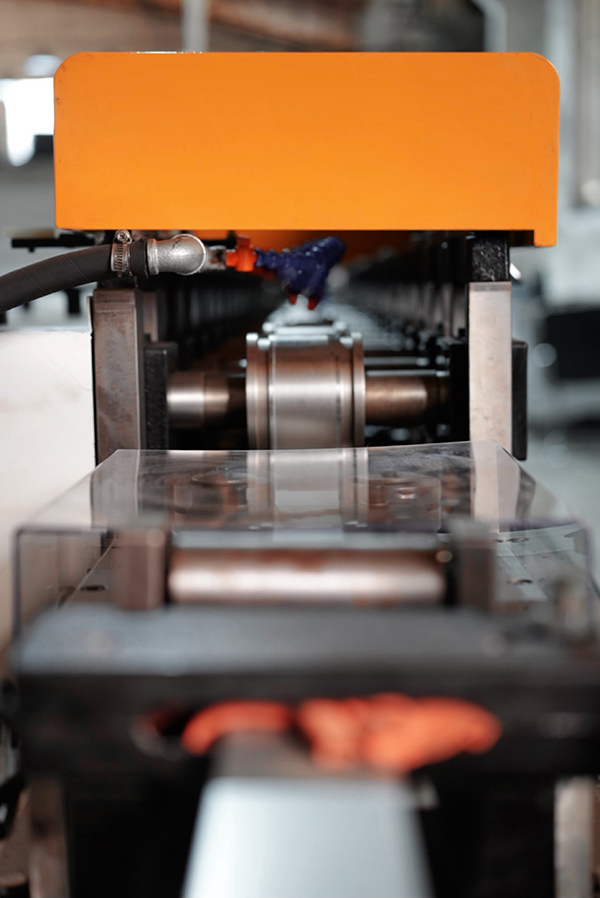

However, the products of the undermount drawer slides require a stable and efficient production rhythm. Unlike manual production, precision manufacturing continues to output high-quality products and rethink how to break through the status quo to meet the needs of Youlisi’s customers for products.

Youlisi began to lay out an industrialized smart manufacturing system since 2018, which is designed by the best intelligent manufacturing R&D team in China to jointly build an undermount drawer slide production line. From material forming - product processing - product assembly- testing- packaging, full line automation, we’re confident that based on this system, not only drawer slide, but also buffer, push to open, caster and leveler leg can have greater consistency. “Precision machining allows us to increase automation capabilities while enhancing production output and minimizing error and avoidable costs, we aim to make fast turnaround and keep greater consistency of reproducing. That’s the reasons why we insisted in developing drawer slide precision manufacturing although devoting huge cost.”said by manager of Youlisi, Mike.